Each week we share business ideas and opportunities that you can use to build your next big business.

We’ve decided to experiment with the format a bit. The past few newsletters were getting too long and the content curation section was getting cut in people’s inboxes. So, we’ve decided to split the newsletter into Industry Deep Dives on Wednesday and the Content Curation on the weekends. Let us know what you think about this experiment!

In today’s Newsletter, we’ll do a deep dive into Cold Storage Warehousing in India and the business opportunities it brings!

Today’s Newsletter is Part 2 of our series on Warehousing in India - click here to read Part 1.

🥶 Cold Storage Warehousing 🥶

In late 2020, when the first Covid vaccines from Pfizer started rolling out in Western countries, there were discussions on whether or not we could get these vaccines in India. The major sticking point was India’s lack of a robust Cold Chain which would keep the vaccines at the incredibly cold temperatures they needed to be stored.

A cold chain is a low temperature-controlled supply chain. An unbroken cold chain is an uninterrupted series of refrigerated production, storage and distribution activities, along with associated equipment and logistics, which maintain quality via a desired low-temperature range.

An essential link in this Cold Chain is Cold Storage Warehousing.

What are the other parts of the Cold Chain?

Cold Storage – Facilities that store goods and products waiting to be transported.

Cooling Systems – Systems that bring food up to and keep it at an appropriate temperature during all aspects of the supply chain, including processing, storing and transporting.

Cold Transport – Ensures goods remain at stable temperature and humidity levels.

Cold Processing – Facilities that allow for processing goods with sanitation in mind.

Cold Distribution – Deals with loading boxes or crates and pallets to distribute goods.

What Industries need Cold Storage?

Pharmaceuticals - For vaccines, there are different types of cold chains such as ultralow (-70°C), frozen (-20°C) and refrigerated chain (2 - 8 °C).

Grocery Delivery - especially meat brands like Licious & Fresh to Home.

Flower Delivery - one of the biggest use cases of the cold chain. Here’s a deep dive into the cold chain for Floriculture.

Chemicals - photographic film and other chemicals react differently when stored at different temperatures.

Existing Cold Storage Infrastructure in India

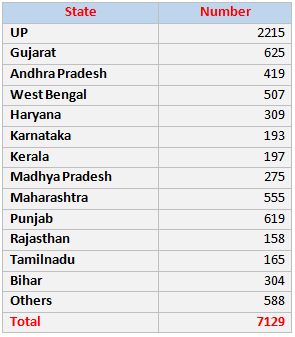

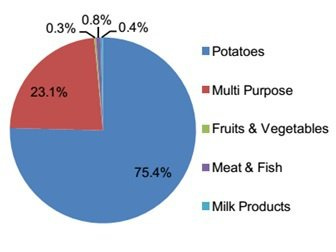

India has about 8,200 cold storage facilities as of 2020, 75% of which are suitable only for storing single commodities.

About 60% of cold storage capacity is concentrated in the states of UP, Gujurat, West Bengal, and AP out of which storage of potatoes accounts for ~75% of the capacity.

Cold Storage contributes 43.7% of the total revenue from the cold chain industry and only 36% of players have a capacity below 1,000 metric tonnes.

Government Policies and Regulations for Cold Storage in India

Cold Chain Scheme

Launched in 2008 by Ministry of Food Processing Industries

Eligibality Criteria:

Minimal processing Centre at the farm with facilities such as weighing, sorting, grading waxing, packing, pre-cooling, Controlled Atmosphere (CA) / Modified Atmosphere (MA) cold Storage, normal storage and IQF.

Mobile pre-cooling vans and reefer trucks.

Distribution hubs with multi product and multi CA/MA chambers, cold storage/ Variable Humidity Chambers, Packing facility, CIP Fog treatment, IQF and blast freezing.

Irradiation facility.

Notes:

To avail financial assistance, any two of the components, from (1), (2) or (3) above will have to be set-up.

Irradiation facility is treated as a stand alone one for the purpose of availing grant.

Over the last eleven years, the government has initiated policies such as profit-linked tax deduction, allowing FDI and other financial assistance, to support integrated cold chain management and encourage the private sector to develop facilities.

Demand and Growth of Cold Storage

The cold chain capacity in India will grow aggressively to 40.7 million metric tonnes of total perishables by 2023, rising 8.2% from 2020, consistent with a Colliers report. The segment is predicted to become more organized and attract more interest from third party logistics providers and institutional funds.

Problem Areas

Initial Investment cost is very high

Cold storage facilities are hugely capital intensive, but can fetch gross yields of about 12%, with a break-even period of nine years and higher rental premium of about 3-4 times that of traditional warehouses. From our conversations with industry players, you can expect to pay about Rs. 4,000 to Rs. 5,000 per sq. ft. of cold storage which is 2-3x the price of building a more conventional warehouse.

Constant Supply of Electricity

A universally Indian problem but a solvable problem. Solar + Cold Storage is a solution that’s already on the market. While installing solar panels increases initial investments, operational costs will be lower due to less electricity use.

Other Problems

Lack of organized/efficient supply chain across the country currently leads to wastage of agricultural produce.

Protection equipment required while entering storage units since they are at very low temperatures

Maintaining temperature during transfer and supply - broken links in the Cold Chain.

Current network is broken with concentration in a few states.

Existing Market Players

Snowman Logistics - 240crs Revenue in FY21

TCI Cold Chain Solutions - 361crs Revenue in FY21

Coldman Logistics - 68crs Revenue & 18crs Loss in FY21

EcoFrost - 47crs Revenue & 4.8 crs loss in FY21 - Ecozen - portable cold storage facility - powered by Solar Panels.

Cool Crop - 1cr Revenue in FY21 - Decentralised Cooling warehouses/ CaaS (Cooling as a Service)

Indospace - Global fund investing in Warehousing in India

Opportunities for Cold Storage

Developing Software & Hardware for Cold Storage Facilities

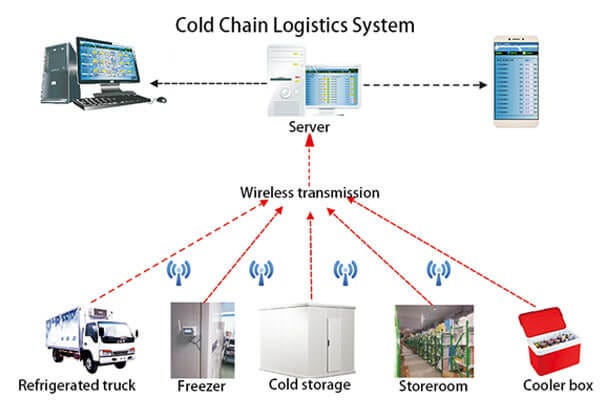

Technologies such as Artificial Intelligence (AI) and Internet of Things (IoT) is paving their way in cold chain storage optimizing the products effectively and helping in a reduction in wastage.

Temperature monitoring devices are being developed which will help in detecting temperature, humidity, or pressure.

Warehouse Monitoring & Management System for Cold Storage

A traditional Warehouse Management System (WMS) focuses primarily on inventory management. However, it gets far more complicated with Cold Storage because of the temperature regulation - especially if different parts of the facility need to be at different temperatures.

IoT Sensors will need to be integrated into each piece of the entire Cold Chain along with a software for monitoring from a single dashboard. A complex issue with multiple solutions.

3PL Players with Multi-Purpose Cold Chain Facilities

The vast majority of cold storage in India is single purpose for vegetables. However, multi-purpose 3rd Party Logistics (3PL) facilities can introduce flexibility in the use of cold storage for brands.

Organising the Industry

Organized development in this segment as the current infrastructure is primarily fragmented and undersupplied. Organised infrastructure would lead to lowered wastage and increased shelf life of perishable products.

Other Opportunities

Opportunity to expand out of just food produce.

Protective Equipment manufacturing and supply.

Training on using cold storage software and monitoring facilities

Tech development on application for constantly monitoring produce + temperature.

Shared warehouse spaces near produce distribution centres with mobile applications to monitor the supply.

Cooling as a Service (CaaS) is a pay-per-service model for clean cooling systems, which eliminates upfront investment in clean cooling technology for customers who instead pay per unit of cooling they consume, strengthening incentives for efficient consumption.